How to make a wooden bed with your own hands, step-by-step instructions

In furniture stores, the price of designer models, for those on which the sign "handmade" hangs, significantly exceeds the mark of a reasonable and possible. Wooden beds look very stylish and modern. The high cost of materials makes it less popular. Significant savings can be made if you make a bed with your own hands from wood without the involvement of specialists. Self-production will allow you to create a unique model suitable for the design of the room in which it will be located.

How to choose wood

Before starting to make a bed, you need to choose the wood from which the furniture will be made. All breeds are conventionally divided into two groups:

- Soft;

- Solid.

Soft breeds include:

- Cedar;

- Pine;

- Tui;

- Spruce;

- Alder tree;

- Aspen;

- Lipu.

Hard rocks include:

- Birch

- Ash;

- Oak;

- Beech;

- Nut;

- Maple.

Each group has its own advantages and disadvantages. Wood has only one particular species. A brief description of the popular materials for a wooden bed with their own hands is given below in the corresponding table.

| № | Title | Breed | Material characteristics, advantages and disadvantages |

| 1 | Alder | Soft | It is a popular material due to its low price category. When drilling, alder cracks, so when making furniture from it, it is not recommended to use nails as fasteners. Main advantages: low price, resistance to high humidity (does not absorb water). |

| 2 | Pine | Soft | Low price category. Disadvantages: wood is easy to crack, does not withstand heavy loads. Advantages: antiseptic properties, air disinfection, not amenable to the effects of wood pests. |

| 3 | Linden | Soft | It gives in to the negative influence of external factors, it is adversely affected by sunlight, high humidity and dry air. Linden is used for the manufacture of internal parts of furniture, since it is resistant to mechanical damage. |

| 4 | Oak | Solid | Oak furniture is durable and durable. It easily withstands heavy loads, has resistance to adverse external factors. Furniture from this type of wood is elite. The main disadvantage: a high price category, which makes the oak rare available only to a few. |

| 5 | Ash | Solid | Ash is fed to mechanical damage, does not bend under the weight, does not tend to deform over time. It is expensive, but the durability of the material justifies the high price. Requires protection and regular handling from wood bugs. |

| 6 | Birch | Solid | During fastening of elements, the material does not lend itself to split. It has high strength, but the average price category, which makes birch popular. The main drawback is the need for special treatment from the fungus, which easily infects the array. |

| 7 | Beech | Solid | Beech is a dense material. With proper processing, beech furniture lasts a long time. Negatively affects the wood temperature and humidity. The material is able to deform under the weight of human weight. It belongs to the middle price category. |

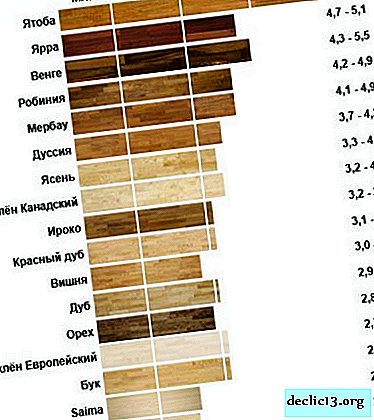

Wood hardness

Wood hardness Wood species

Wood speciesCalculation of the amount of materials

Below you will find the calculation of the necessary materials for wooden beds with your own hands. You can make this bed from solid pine, because it is cheap. You can choose more expensive materials. The calculation of the required amount of wood is given in the table below.

| Material | Quantity, pcs | Size in mm | Appointment |

| Board | 3 | 50*100*2400 | Support beams |

| Board | 3 | 50*24*2400 | Decorative finish |

| Board | 19 | 25*75*2400 | Making the bottom of the slats |

| Board | 4 | 200*25*2400 | Frame manufacturing |

| Timber | 1 | 2400*100*100 | Legs |

Materials

MaterialsThe amount of material is indicated for the manufacture of a bed with a mattress size of 2000 by 1500 mm. This is not a single bed; a bed of this size is suitable for two. If the mattress is of different sizes, you only need to slightly change the length of the boards, but the manufacturing algorithm and sequence of actions remains unchanged.

In addition to wood, you will also need:

- Self-tapping screws 30 mm;

- Self-tapping screws 60 mm;

- Self-tapping screws 50 mm;

- Acrylic varnish (for decorative decoration);

- Stain;

- Filling on wood;

- Solar glue.

The aforementioned wooden elements are indicated based on the manufacture of furniture without a headboard. Adding a carved headboard, you can create an antique bed with your own hands. In this case, the headboard will not play the role of the headboard, but rather will act as a decorative element.

Fasteners

FastenersManufacturing items

The sequence of manufacturing elements for the future bed includes cutting materials, polishing them, drilling holes for screwing screws at an angle and fastening furniture elements with wood glue and screws.

Frame

To make a frame, two boards with dimensions of 2.5 × 20 × 205 cm and two boards with dimensions of 2.5 × 20 × 148.5 cm are cut. How to make a frame yourself:

- Cut boards are cut at the required length with a jigsaw;

- Using a grinder or a planer, the wood is polished;

- All four boards are placed at an angle of 90 degrees relative to each other. Check the connection angle using a square. For more reliable fastening, you can use metal corners at 90 degrees;

- For fastening with screws at an angle, we make special holes, and after joining the wood with screws, the joints are fixed with carpentry glue.

The corner of each board should be sharpened and rounded. This will ensure not only safety in operation, but also protect the carpenter making the bed from wounds, scratches, splintering and cuts.

For this mount, 30 mm screws are used. Remains of wood glue, until they are dry, are cleaned with a damp cloth. To process the bed frame with your own hands, you can use not only electric, but also hand tools on wood.

We cut boards of the right size

We cut boards of the right size Grind them

Grind them Fasten corners

Fasten corners Assembling the frame

Assembling the frameBase

After the frame is processed, you can begin to manufacture the basis for the rack bottom. It is advisable to install the rails themselves after assembling the bed, so that it is more convenient to build the remaining parts. Step-by-step diagrams of how to make a bed base:

- For the manufacture of frames used boards 50 * 100 * 2400 mm;

- They need to be cut in length so that it is 202 cm;

- All 3 wooden boards are mounted along the base of the bed;

- They can be attached using self-tapping screws and wood glue;

- The side boards are fastened with wood glue (clamps can be used for reliable bonding), and after it is dried, it is fastened to the bed frame with self-tapping screws every 25 cm. Self-tapping screws are used with a length of 50 mm;

- Before screwing in the screws, it is necessary to prepare holes for them. This simple operation will facilitate the work and help to avoid cracking the tree;

- To make a homemade wooden bed with your own hands securely connected, fixing the elements to the ends of the frame is not only self-tapping, but also glue.

We select lamellas by size

We select lamellas by size Be sure to indent the same way.

Be sure to indent the same way. We fasten them with lamellas

We fasten them with lamellas Features of lamella insertion

Features of lamella insertionHeadboard

When making a bed from solid wood, the headboard should be used as an element of decor. A headboard is not provided for in a wooden bed, since wood furniture is considered a sign of wealth and luxury. When a carved bed is made of wood, the headboard must be selected in accordance with the dimensions of the base of the structure.

So that the wooden bed does not lose its sophistication and luxury, the headboard must be created either using a wood milling machine or ordering a finished one. If the external design is not as important as the functionality of the bed, you can make a bed without a headboard, or attach it later, after purchase. The headboard assembled from several details detracts from the beauty and sophistication of expensive handmade wooden furniture.

The headboard needs to be processed and painted with the same materials that were used to create a beautiful frame and base. In this case, the bed will be both functional and beautiful.

Cut the part of the right size

Cut the part of the right size Make holes

Make holes Glue foam

Glue foam Upholstered with fabric

Upholstered with fabricSupports

Legs will be used as a support. We make them from a wooden bar. We do it like this:

- 6 elements 10.5 cm long are cut from a wooden beam 10 * 10 cm (the height of the legs can be changed according to the data of a specific project);

- Such legs can be made more beautiful if the lower corner of the support is made slightly beveled. This is done at will;

- After that, each leg lends itself to rounding of the ends, and then it is ground;

- Under each support, and there are three of them (two lateral and one central), two legs are placed. If it is decided to decorate the legs decoratively by mowing the support area, it is not recommended to reduce the support area of the central legs;

- Under the central support the legs can be fixed not at the edges, but closer to the center. Before fastening the parts with self-tapping screws, holes must be drilled under them.

On the supports you need to make marks in the places where the screws are attached. This will help to prevent the contact of self-tapping screws and splitting the tree from the load.

Choose the bar of the desired thickness

Choose the bar of the desired thickness Determine the optimal length

Determine the optimal length Cut to mark

Cut to mark Make bevels

Make bevels Fasten the legs

Fasten the legsFasteners for solid products

During the manufacture of wooden beds, special attention is paid to fasteners. Among those you will need:

- Wood screws (of different lengths);

- Corners made of metal with a rounded stiffening rib (to give the wooden structure greater reliability);

- Nails (not suitable for any wood).

For more reliable fastening of parts, it is recommended to use clamps.

How to choose screws for fastening two specific parts:

- Measure the thickness of the part to which the second part will be attached;

- Measure the thickness of the part that attaches to the core;

- Add both values (in mm);

- Subtract 10 mm from the received figure;

- The obtained value will denote the length of the self-tapping screw necessary for fastening 2 of the above parts.

For example:

- The main part is 55 mm thick;

- The thickness of the attached part is 25 mm;

- 25 + 55 = 80mm;

- 80-10 = 70mm.

To fasten two parts (55 and 25 mm) with a total thickness of 80 mm, it is necessary to use self-tapping screws 70 mm long.

Assembly

After fixing the legs, you can return the structure to its original position. Now it stands as it would during operation. Further assembly of the bed includes the decoration of the two end and one long sides with decorative boards, as well as the creation of a slatted bottom, on which the mattress will be laid in the future.

How to make homemade slats for the mattress:

- Since the length of all the rails will be the same, you can measure the length for only one rail, and you can create the rest by drawing correspondences between its dimensions and the dimensions of the first (reference);

- Each rail must be cut off, sanded and holes made for fastening in it;

- The slats are laid on the bed base at an equal distance (with respect to each other), and are attached with self-tapping screws screwed into the prepared holes to the side and central supports. Before attaching the rails, mark the places for attaching the legs to the frame so that during screwing in the screws do not damage the wood with excessive load. The distance between the screws that attach the legs and slats should be at least 5 cm.

Making rails to size

Making rails to size Grind them

Grind them Fasten them to the base

Fasten them to the baseDecor Options

Three boards are used as decorative finishes. They can be decorated with carving, which is done on a milling machine, or engraving. How to fix decorative elements:

- After cutting and sanding, decorative boards are attached to the top of the frame;

- Joiner glue is applied to the ends of the wooden planks, and the planks are pressed with clamps until they are fully fixed;

- This decorative finish will not only reduce the risk of injury sleeping on the ends of the frame boards, but also give the bed a more beautiful look;

- It is desirable to clamp decorative boards with clamps using small wooden cuts. They increase the area of pressing 2 boards to each other, and also protect decorative boards from traces left by clamps.

In addition to attaching decorative boards, as a decor, you can use a carved headboard, or choose bed drawings that include the presence of a foot. As a beautiful decorative element, you can create a special place for the cat in the lower part of the bed, or rather under it. Make this place easy with a few boards. For reliability of fastening, and also that the bed did not creak, all openings prepared for self-tapping screws after finishing work need to be putty putty on wood. In this case, the bed will not creak during sleep.

As you can see from this article, which includes step-by-step instructions on how to make a bed out of wood, if you have enough tools and materials, you can work at home. Wooden furniture does not belong to the class of simple furniture, it is considered to be elite, and therefore is very expensive. There is simply no other way to save on luxury furniture, except to make a bed with your own hands.

Drawings and schemes